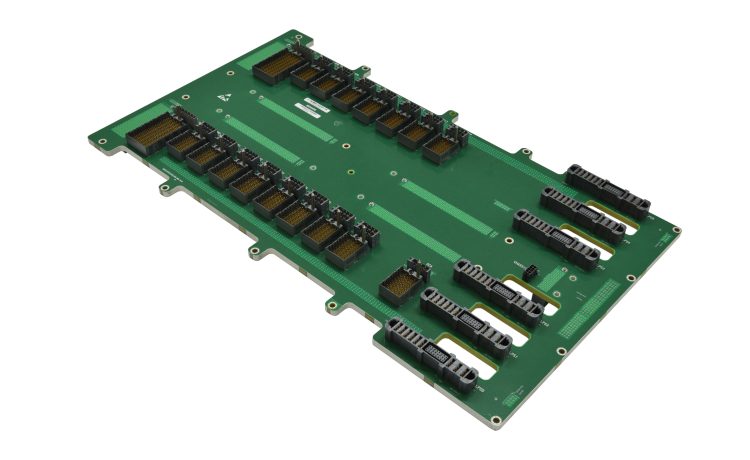

Amphenol’s experience in developing leading-edge, end-to-end custom backplane, midplane and system solutions is unique in the industry. With over 30 years of designing, manufacturing, and testing of high-speed backplane assemblies, Amphenol has emerged with a leadership position in the industry, delivering optimised cost against critical time-to-market requirements. Combining engineering expertise with investment in the latest technologies has enabled the delivery of tested nano compliant technology in today’s leading edge laminates allowing performance of 50G plus to meet both today’s and tomorrows data transmission requirements.

Amphenol can provide vertically integrated assemblies utilising various divisions within Amphenol including Connectors, PCBs, Cables and Power products including Bus Bars.

In order to deliver against all of our customers’ custom backplane requirements, we also leverage our relationships with outside connector vendors and low-cost region fab suppliers.

Our experienced field (FAE) and customer engineering teams are on hand to ensure that your custom backplane system requirements are met in the most efficient manner. From concept to finished design deliverables the team’s unrivalled knowledge of the latest technology will guarantee that your design custom backplane is completed efficiently and cost-effectively the first time.

Amphenol BSI design resources and capabilities also extend to working on solutions for customers who utilise Open Industry Standard Backplane architecture, but require customised features. As members of VITA and PICMG organisations, we have access to all the data & knowledge of cPCI, ATCA, VPX, VXS & VME open Industry standards, but can present cost and performance solutions customised to the customers specific requirements. This gives us a distinct advantage as standard communications applications in the Industrial, Commercial & Defence Aerospace, require more bandwidth.

Amphenol’s early involvement in the custom backplane design development process can play a positive role in improving system performance and reducing system cost. ABSI’s unique ability to leverage the experience of our sister divisions in high-speed PCB manufacture (APC) and connector assembly (ATCS / AFCI) means that the team has the ability to view the signal link in the system from a holistic point of view leading to a cleaner and more stable design.

This design work is backed up by industry leading Signal Integrity (SI) simulation which allows our team to predict the design performance and manage any signal issues before the design is closed.

In addition, our team can predict the custom backplane performance and manage any signal issues before the design is closed, by using an industry leading Signal Integrity (SI) simulation.

Additionally, our experience in PCB and connector design and manufacture allows us to carry out detailed Custom Backplane Design for Manufacture, Design for Assembly and Design for Test in advance of completing a design or on your existing products to offer our customers value engineering opportunities for performance and cost.

As bandwidth / speed requirements increase, the assembly of Custom Backplanes and Midplanes require increasingly sophisticated assembly and test solutions to ensure signal fidelity at high speed and also to future-proof your design custom backplane for any card capacity upgrades you will have planned. Amphenol BSI collaborates with key equipment partners to ensure that press and test solutions are developed and in place to intercept PCB and Interconnect roadmaps. Our manufacturing facilities in China and Mexico have mirrored capabilities to support geographic agility and class-leading press and test equipment.