Amphenol-BSI have an engineering team structure set-up based in USA, Mexico, Europe, China and India providing Design and Manufacturing to a customer base anywhere in the world.

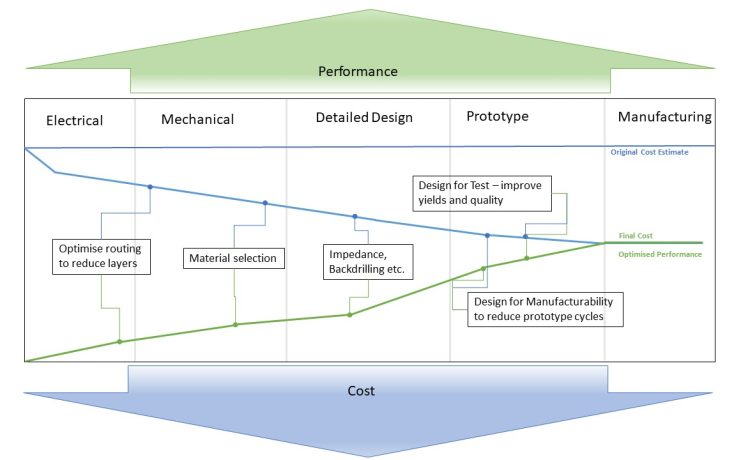

Our engineering team use DFx procedures and work directly with customers and factories on these procedures:

1) Design for Manufacture (DFM) – PCB

BP FAE reviews pcb design and works with pcb supplier on providing feedback/issues with layout parameters vs suppliers capabilities.

GE and PE reviews the product data package and verifies it meets minimum requirement for build. Any issues are referred to customer and gaps in requirements clarified.

2) Design for Assembly (DFA) :

GE and PE review the design and check it meets best practice press-fit, SMT, thru hole soldering, mechanical assembly requirements.

3) Design for Test (DFT) :

GE and PE Review design to confirm test strategy for proto build and identify and note any test coverage gaps.